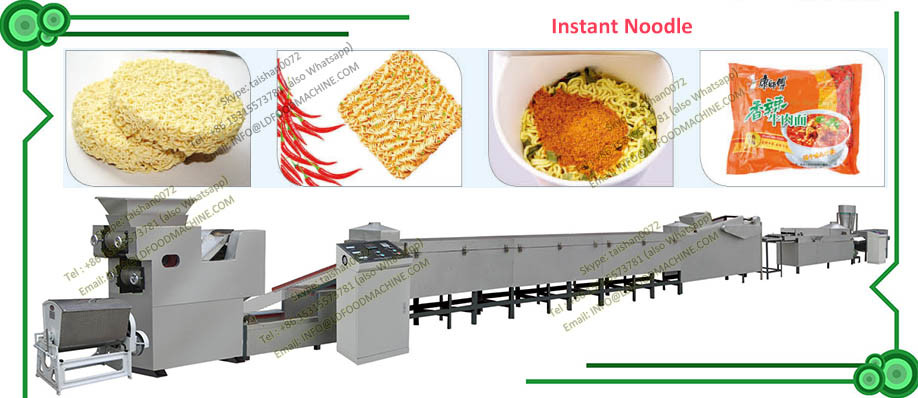

| Condition:New | Type:Noodle |

| Production Capacity:11000 pcs/8h | Place of Origin:Shandong, China (Mainland) |

| Brand Name:LD | Model Number:LDS-I / II |

| Voltage:220V/380V or adjustable | Power(W):80.5kw |

| Dimension(L*W*H):23000x1500x180 | Weight:8t |

| Certification:ISO9001 | Warranty:12 months |

| After-sales Service Provided:Engineers available to service overseas | Name:Automatic konjac reaLD in knots |

| Power:Enerable saving instant make line | Function:multi-functional instant production machinery |

|

|

|||||||

Replace Pump of Automatic konjac reaLD in knots Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| dough kneading machine 1kg | 44,45 mm | 85 mm | 49,2 mm | 33,2 kN | ||||

| mockmill kitchenaid attachment | 35 mm | 572.4 lb | 7.1 kN | 25,5 kN | ||||

| flour mixing machine 20kg | 170 mm | 260 mm | 42 mm | 492,6 | ||||

| cookwell instagrind service center | 420 mm | 520 mm | 100 mm | 1359 kN | ||||

| flour mixing machine 2kg | 60 mm | 95 mm | 18 mm | 49.9 mm | ||||

| kitchenaid wheat grinder | 31 kN | 7 Days | 1/2 in | 31171533 | ||||

| flour mixer machine for home | Take Up | 458 mm | 44,45 | 12 | ||||

| atta dough making machine | 1-15/16 in | 3.833 in | 7/8 in | 1-1/2 in | ||||

| flour mixer machine for bakery | B00152 | 260 mm | 7/8 in | 0.38 in | ||||

| flour mixing machine for home price | 60 ° | 7 Hz | 5.7500 in | 88.2 mm | ||||

| flour kneading machine price | 40 | Ball Bearing | 42 mm | 1600 N | ||||

| flour mill attachment for mixer grinder | 13.75 Inch / 349.25 Millimeter | 30,2 mm | 12 | Oil Seals | ||||

| atta kneader machine price | 35 mm | 90 mm | 34 mm | 34 mm | ||||

| wheat flour mixing machine | Lip | 1 Inch / 25.4 Millimeter | 34100 | Clear Anodize | ||||

Replacement Bearing of Instant Noodle Process Line data list | ||||||||

|---|---|---|---|---|---|---|---|---|

| wheat flour mixing machine | 19,05 mm | 47 mm | 11,112 mm | 46 mm | ||||

| atta mixing bowl | 82.55 mm | 180 mm | 6.76 kg | 1.188 Inch | 30.175 Millimeter | ||||

| flour kneader | 0 Inch | 0 Millimeter | 4.125 Inch | 104.775 Millimeter | 0.564 | N/A | ||||

| atta kneader machine price | 12 | http://www.timken.com | 1.703 | N/A | ||||

| best atta kneader | 1.188 Inch | 30.175 Millimeter | 1.567 Inch | 39.8 Millimeter | 0.61 | N/A | ||||

| flour kneading machine price | 0.787 Inch | 20 Millimeter | 15.5 mm | 1.4 | N/A | ||||

| flour mixing machine for home price | Not Rated | 75 | 0.014 | N/A | ||||

| mockmill kitchenaid grain mill attachment | 280 mm | 420 mm | 10 mm | HPCA-62 | ||||

| atta dough making machine | 47 mm | Not Split | 180 mm | Taper Roller Bearing - Double Row | ||||

| flour mixer machine for home | 75 mm | 135 mm | 82.55 mm | 31171530 | ||||

| maida mixing machine price | 12 mm | 32 mm | 420 mm | 20 | ||||

| chapati flour mixer | Single Row | Spherical | Normal Duty | Flat | 1100 RPM | 3 mm | ||||

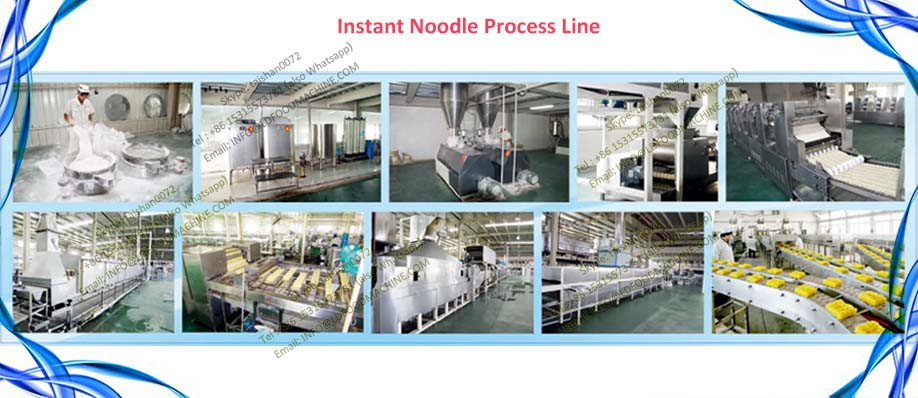

Customer Cases For Automatic konjac reaLD in knots For Factory In 2022 | |

|---|---|

| 1 | High Quality Pasta Manufacturing Machinery Macaroni Machine Line Sale In Morocco |

| 2 | Semi automatic instant noodle process machines instant noodles production line For Sale South Africa |

| 3 | Automatic Mini Instant noodles processing line/making machine Sale In Brazil |

| 4 | Full automatic instant rice production line,nutrition artificial rice making machine For Sale Morocco |

| 5 | Hot sale instant noodle production line For Sale Argentina |

| 6 | instant noodle making equipment rice noodle machine ramen noodle production machine Process In Argentina |

Customer Have Factory Case Of Instant Noodle Process Line At 2021 | |

|---|---|

| 1 | Instant Noodles Line Fried Instant Noodles Making Machine Processing Line From China Supplier Process In Zimbabwe |

| 2 | Commercial Instant Noodles Indomie Noodle Making Machine Price in India For Sale Turkey |

| 3 | instant noodles processing line For Sale Argentina |

| 4 | Automatic Rice Noodle Machinery / instant Rice Noodle Production Line For Sale Ethiopia |

| 5 | Instant Noodle Processing Line Noodle Steaming Machine Noodle Machine For Sale Morocco |

| 6 | Automatic instant buckwheat soba noodle machines / industrial non-fried extruding cereal flours instant noodles production line Sale In India |

Automatic konjac reaLD in knots Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Online Shopping Instant Noodle make machinery | 1 Set | US$1529 | US$6654 |

| Noodle Pressing machinery Manufacturer for Bag Fresh | 1 Set | US$1034 | US$7533 |

| Macaroni Pasta Production Line / LDaghetti Production Line | 1 Set | US$1551 | US$6250 |

| fully automatic instant make machinerys plant | 1 Set | US$1203 | US$5643 |

| Low price cost-effective Instant Noodle food make machinery | 1 Set | US$1359 | US$5356 |

| Fried instant production line | 1 Set | US$1254 | US$7544 |

| Factory price fried instant noodle machinery | 1 Set | US$1146 | US$6394 |

| quality fried instant make machinery/Auto make equipments | 1 Set | US$1747 | US$6145 |

| New condition instant noodle production line / make machinery / Plant | 1 Set | US$1179 | US$7506 |

Copyright © 2017 - 2024Jinan ADO Food Machinery Co.,Ltd. All Rights Reserved