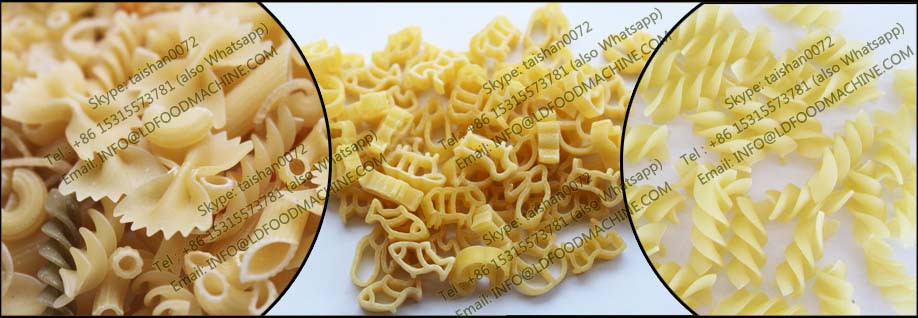

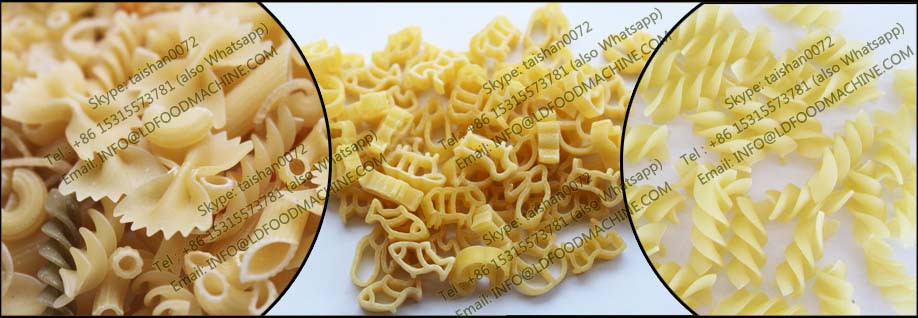

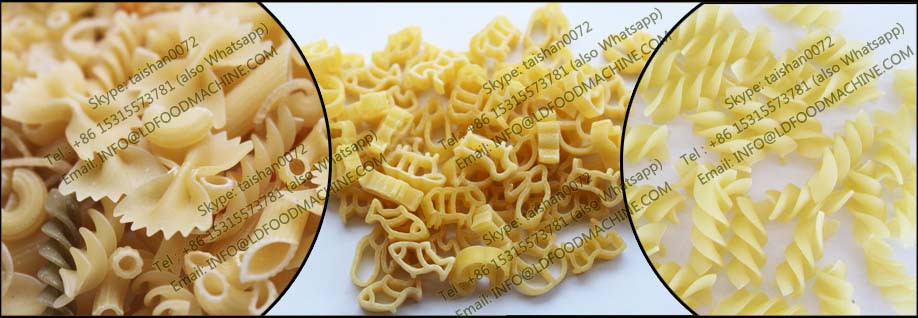

| Condition:New | Type:Noodle |

| Production Capacity:80-100kg/h | Place of Origin:Shandong, China (Mainland) |

| Brand Name:LD | Model Number:LD3000-100 |

| Voltage:220/380v can adjust according different country | Power(W):53kw/62kw |

| Dimension(L*W*H):14x1.8x2.5m/17x1.2x3m | Weight:4.5ton |

| Certification:ISO9001,CE | Warranty:one year |

| After-sales Service Provided:Engineers available to service overseas | Name:Macaroni pasta food extruder machinery/pasta production line |

| Function:multi-functional psata production line | Brand:China top sale pasta food machinery/pasta macaroni production line |

Model |

Output Capacity |

Supply VoLDage |

LD10/100 |

100 ~ 150 Kg/h |

380V/50Hz Three phases or 220V/60Hz Single phase |

LD10/90 |

100 ~ 150 Kg/h |

|

LD10/120 |

120 ~ 200 Kg/h |

|

LD10/75-2 |

100 ~ 300 Kg/h |

Replace Seal of Macaroni pasta food extruder machinery/pasta production line Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| mockmill kitchenaid grain mill attachment | 130 mm | 200 mm | 3,16 Kg | 33 mm | ||||

| flour kneader | 45 mm | 85 mm | Self Aligning | 19 mm | ||||

| flour dough maker | 65 mm | Large / With Inner Case / Heavy Duty / With Spring Lock and Spring-Cover | 6.06 kg | 65.1 mm | ||||

| dough kneading machine 1kg | Ball | 1.46 | 21.2 | 1.181 Inch / 30 Millimeter | ||||

| flour mixing machine for home price | M6x1 | Deep Groove | With Snap Ring | 46.72 | Cast Iron | ||||

| atta dough making machine | 3.15 Inch | 80 Millimeter | 5.512 Inch | 140 Millimeter | - | 3.62 Hz | ||||

| chapati flour mixer | 1.575 Inch | 40 Millimeter | 3.543 Inch | 90 Millimeter | 0.903 | 340 mm | ||||

| flour mixing machine 2kg | 35 mm | 82.6 mm | Large / With Inner Case / Heavy Duty / With Spring Lock | 47.9 mm | ||||

| kitchenaid flour mixer | 2.0625 in | HDS2 | 1 mm | Bearing | ||||

| maida mixing machine price | 190 mm | 340 mm | 45.200 kg | 92 mm | ||||

| atta mixing bowl | Lock Washer (W12) | http://www.fag.com | Lip | 31171532 | ||||

| mockmill kitchenaid attachment | Lock Washer (W12) | 3.62 Hz | 55.5 mm | 1.991 | ||||

Replace Bearing of Spaghetti Process Line Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| kitchenaid flour mixer | 648 mm | 848 mm | 3800 rpm | DD (Contact Rubber Seal) | ||||

| flour kneader | 200 mm | 310 mm | 24 mm | 51 mm | ||||

| atta kneading machine price | 76,2 mm | 139,982 mm | 139,982 mm | 200x310x51 | ||||

| grain mill attachment | 7 Days | 800MM Shaft Dia; 840MM Housing Bore; 20MM Nominal Width; Nitrile Lip; Solid Seal; 20MM Actual Width; Spring Loaded; 1 Sealing Lips; Stainless Steel Garter Lip Retainer; Steel Case Construction; HDS1 Seal Design Code | 11.79 | 139,982 mm | ||||

| flour mixer machine for bakery | 0.787 Inch / 20 Millimeter | 9.843 Inch | 250 Millimeter | 4.169 | HDS1 | ||||

| kitchenaid wheat grinder | 1.6250 in | 7.992 Inch | 203 Millimeter | 31.496 Inch / 800 Millimeter | .3750 in | ||||

| flour mixing machine 20kg | 24 mm | 32 mm | 36.5 mm | 20 mm | ||||

| best atta kneader | 60 mm | 110 mm | 2.60 lbs | 36.5 mm | ||||

| mockmill kitchenaid attachment | 1.1875 in | 31171507 | Chrome Steel | ABEC 1 | ISO P0 | ||||

| wheat mixer | 7 Days | Steel | Lubrication Groove & Hole | Center Pull | ||||

| atta mixing bowl | 0.562 in | 248 °F | [Steel] Steel | Flanged Pilot Type | ||||

| flour mixing machine for home price | 5.62 | 1.0000 in | Seal | 6 mm | ||||

| cookwell instagrind service center | 1.1875 in | 31171507 | 1.06 lbs | Nitrile | ||||

Customer Case Of Macaroni pasta food extruder machinery/pasta production line At 2021 | |

|---|---|

| 1 | Wholesale braided lines 300m 8 strands Multicolor High Quality Smooth Fishing Line PE Sale In United Arab Emirates |

| 2 | Fishking Readyship Customized 100M Packaged 8 Weave Braided PE Multifilament Fishing Line Braid 8 Strands Fishing Lines Process In India |

| 3 | macaroni pasta spaghetti processing machine line Sale In Russia |

| 4 | High quality nylon fishing line 100m 4lb-40.6lb strong strength assistant nylon line Process In Zimbabwe |

| 5 | China CE Manufactory Spaghetti Pasta and Macaroni Food Machine Processing Line Price Sale In Turkey |

| 6 | Fishing Fashion Best Multicolor Flying For Fishing Line, 30.5m, WF, Front Weight, Main Floating AccessoriesFishing Lines Sale In India |

Customer Cases For Macaroni pasta food extruder machinery/pasta production line For Factory In 2021 | |

|---|---|

| 1 | Japanese silk Strong strength Multifilament line PE 8 strands braided fishing line For Sale Brazil |

| 2 | High quality automatic industrial continuous extruding rich nutrition pasta spaghetti noodle making machinery made in china Sale In Argentina |

| 3 | Industrial Pasta Macaroni Spaghetti Extruder Processing Machine Line For Sale India |

| 4 | macaroni spaghetti making processing line machines corn pasta food extrusion equipment For Sale Sri Lanka |

| 5 | High Efficiency macaroni noodle price industrial pasta making machine production line CE Process In Brazil |

| 6 | New products high quality factory wholesale super high strength sensitivity nylon fishing line Sale In United Arab Emirates |

| 7 | High Quality Customized Pe Fishing Line Personalized Woven carbon fishing line Sale In Algeria |

Macaroni pasta food extruder machinery/pasta production line Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Hot Seeling Pasta Noodle make machinery -Rice Noodle-Rice Vermicelli | 1 Set | US$1518 | US$5312 |

| Low price automatic pasta/macaroni make machinery | 1 Set | US$1488 | US$5187 |

| LD Pasta machinery at factory price | 1 Set | US$1616 | US$6664 |

| small investment pasta forming machinery | 1 Set | US$1951 | US$6525 |

| professional pasta LDaghetti prices | 1 Set | US$1754 | US$7190 |

| High demand and Capacity Pasta Macaroni food make line in Jinan | 1 Set | US$1295 | US$7228 |

| 3D & 2D snacks pellet pasta food make machinery/pasta production line | 1 Set | US$1390 | US$7540 |

| High quality Long Macaroni Production Line | 1 Set | US$1160 | US$6458 |

| best price macaroni production line/pasta make machinery/pasta processing machinery | 1 Set | US$1085 | US$5562 |

Copyright © 2017 - 2024Jinan ADO Food Machinery Co.,Ltd. All Rights Reserved