| Condition:New | Place of Origin:Shandong, China (Mainland) |

| Brand Name:LD | Model Number:LDN/N-210/1,LDN/N-210/2 |

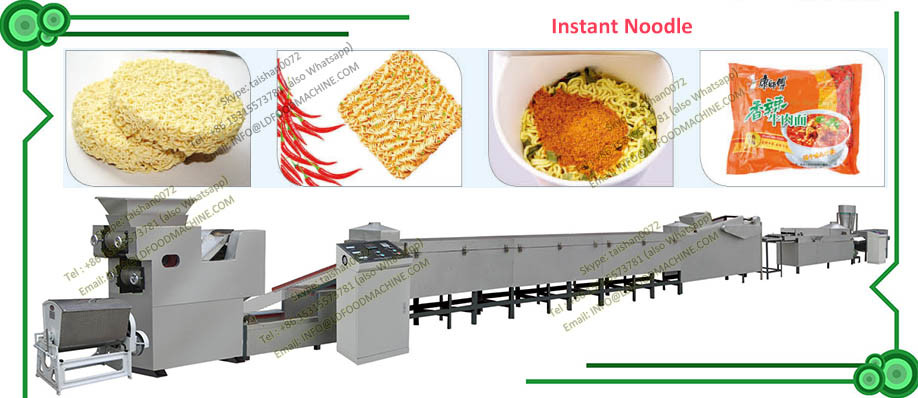

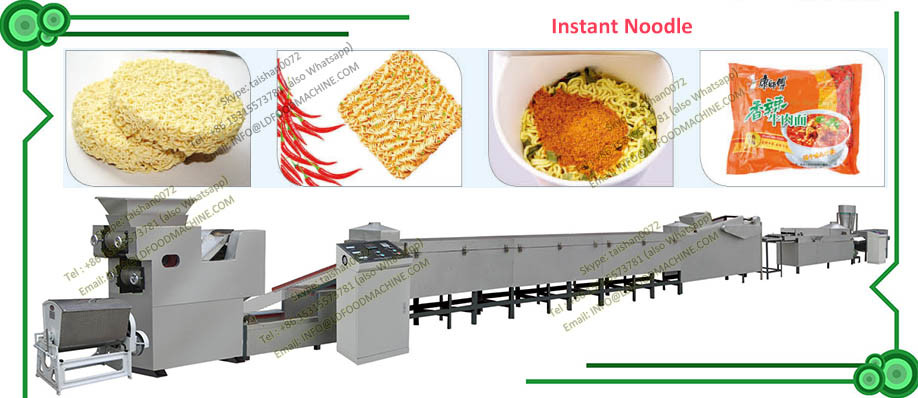

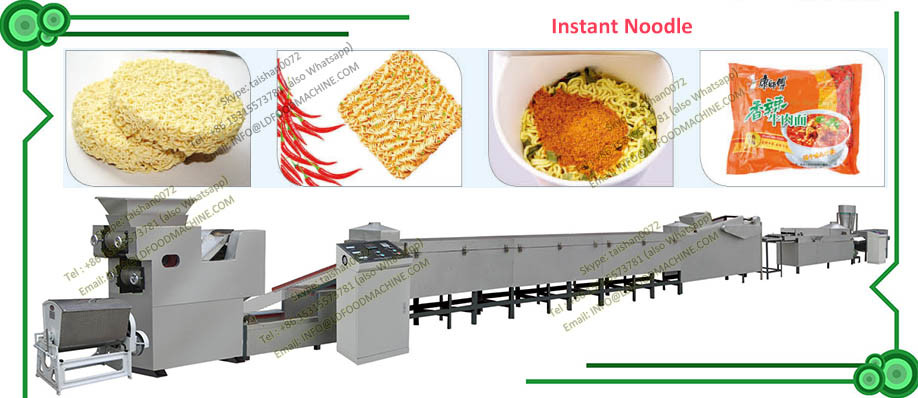

| Application:instant noodle, non-fried instant noodle, baked instant noodle | Voltage:380V/50HZ |

| Power(W):25kw | Weight:8ton |

| Dimension(L*W*H):32000x1500x3500mm | Certification:ISO9001,CE |

| Warranty:one year | After-sales Service Provided:Engineers available to service overseas |

| Machine Name:Enerable-saving instant manufacturing plant | Final Products:Instant noodle, non-fried instant noodle, baked instant noodle |

| Customization:available | Auto Grade:Full Automatic |

| Operate:2-3 persons | Control Method:paint |

| Energy:electricity or Diesel or Gas | Material:Stainless Steel |

| Motor:SIMENS or LDB or China Brand | Instant Noodle Shape:Quadrate or Round |

|

|

Replace Pump of Enerable-saving instant manufacturing plant Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| wheat flour mixing machine | 30 mm | 15 | 52 mm | 0.267 | ||||

| flour mixing machine 2kg | 22,225 mm | 52 mm | 38,1 mm | 2 | ||||

| atta mixing bowl | 175 | 183 | 218 N/µm | 70 mm | ||||

| grain mill attachment | 2.75 Inch | 69.85 Millimeter | 3.33 Inch | 84.582 Millimeter | 80 | 30 mm | ||||

| flour blender machine | 0.54 Inch / 13.716 Millimeter | 21,44 | 0.267 | 82.4 mm | ||||

| cookwell instagrind service center | 1.181 Inch | 30 Millimeter | 2.835 Inch | 72 Millimeter | 0.695 kN | 4 | ||||

| kitchenaid flour guard | 8 mm | 15 mm | 3,4 mm | 6,5 mm | ||||

| flour kneader | 50 mm | 80 mm | 6.72 Inch | 170.7 Millimeter | Seal | ||||

| wheat mixing machine | 70 mm | 110 mm | 85 mm | 83.2 mm | ||||

| atta dough making machine | 70 mm | 100 mm | 80.94 mm | 79.55 mm | ||||

| flour kneading machine price | 1.189 Inch | 30.2 Millimeter | 112 N/micron | Lip | No | ||||

Replacement Bearing of Instant Noodle Process Line data list | ||||||||

|---|---|---|---|---|---|---|---|---|

| chapati flour mixer | Deep Groove Ball Bearings | 35x72x17 | 14800 lbf | 23,800 mm | ||||

| atta mixing bowl | 0.236 Inch / 6 Millimeter | Unit Only | 27 mm | Mechanical Power Transmission | ||||

| flour mixer machine for bakery | 0.0 | N/A | 10.896 | 2.362 Inch | 60 Millimeter | ||||

| grain mill attachment | 0.0 | N/A | - | 10-32 | ||||

| atta kneading machine price | 0.0 | N/A | 2.315 | Speedy Sleeve | ||||

| wheat flour mixing machine | 0.0 | N/A | - | 6 | ||||

| kitchenaid wheat grinder | 0.0 | N/A | 2.58 | SKF | ||||

| flour kneading machine price | 0.0 | N/A | - | 0.236 Inch | 6 Millimeter | ||||

| kitchenaid flour guard | 0.0 | N/A | - | NA49 | ||||

| flour mixing machine 20kg | Double | 0.748 Inch | 19 Millimeter | 5.125 Inch | 130.175 Millimeter | 50 mm | ||||

| flour blender machine | 0.028 | 27 mm | 0.669 Inch / 17 Millimeter | 23,800 | ||||

| maida mixing machine price | 50 | NA49 | 1.8750 in | 35 mm | ||||

| wheat mixing machine | 0.375 Inch | 9.525 Millimeter | 4016.93.50.20 | 72 | 77 | ||||

| atta kneader machine price | Double Row | Single Nut | Non-expansion | Three Lip Urethane Seal | Steel Cage | Steel | 0.5 Inch | 12.7 Millimeter | [Steel] Steel | ||||

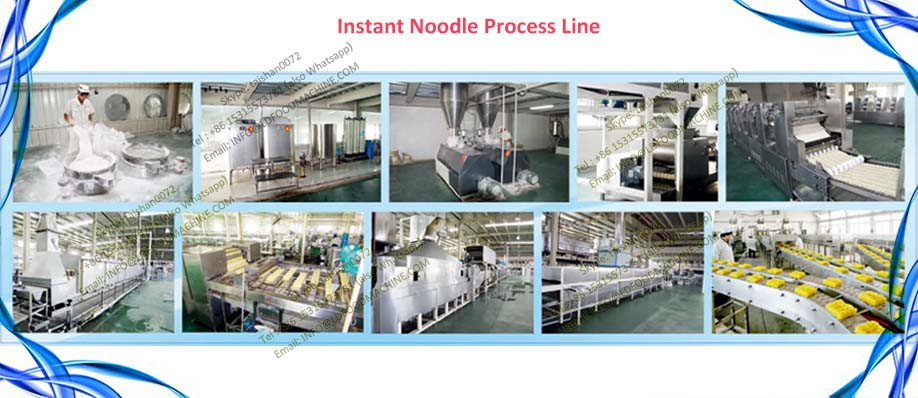

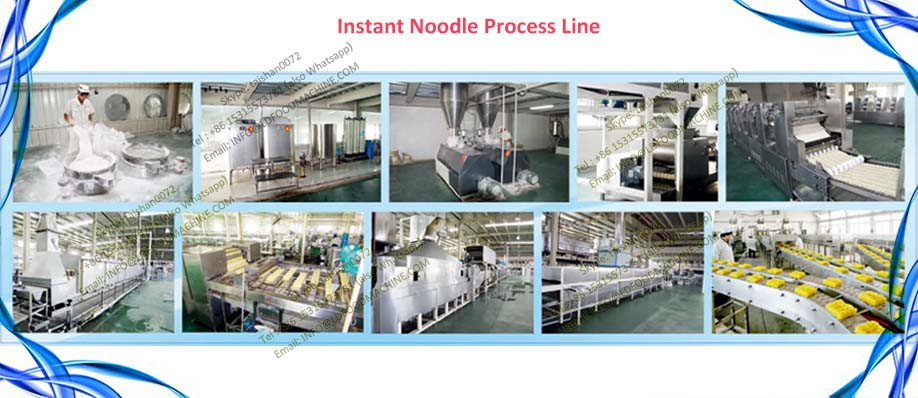

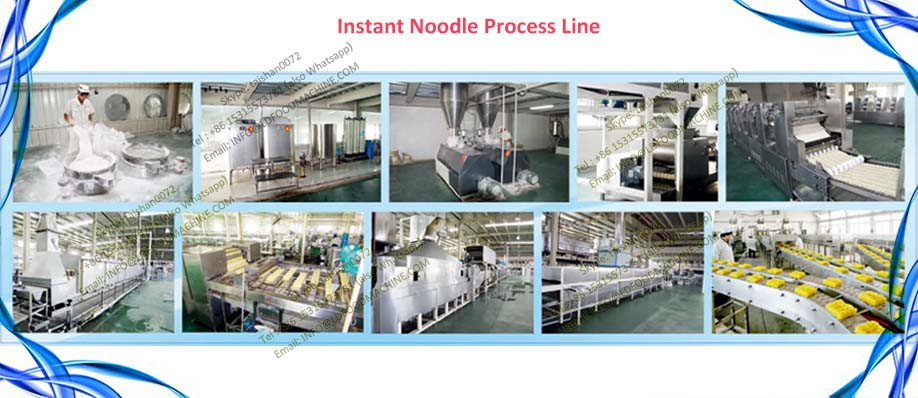

Customer Cases For Enerable-saving instant manufacturing plant For Factory In 2022 | |

|---|---|

| 1 | small automatic Automatic instant noodles production line Process In Morocco |

| 2 | Automatic Instant pasta machine extruder macaroni processing line Sale In Argentina |

| 3 | corn flakes production machine popular corn flakes processing line Process In Russia |

| 4 | Non fried instant noodle production line Process In Zimbabwe |

| 5 | Commercial Maggie Instant Noodle Making Machine For Sale Zimbabwe |

| 6 | Sweet Potato Vermicelli Maker Making Machine Production Line Sale In Argentina |

Customer Have Factory Case Of Instant Noodle Process Line At 2021 | |

|---|---|

| 1 | Instant noodle processing line/Professional noodle production line machine/Noodle making machine price Sale In India |

| 2 | Small scale semi automatic shirataki instant soap noodle production line making machine For Sale Ethiopia |

| 3 | Automatic Fried Instant Noodle Machine Production Line Process In Morocco |

| 4 | Hot Sale Small Fry Instant Noodles Making Wholesale Chinese Automatic Maggi Instant Electric Noodle Machine Sale In Zimbabwe |

| 5 | Commercial use Instant noodle machine production line Process In United Arab Emirates |

| 6 | Manufacturer lowest price instant noodle production line for non-fried and fried instant noodles Process In India |

| 7 | small automatic Automatic instant noodles production line Process In United Arab Emirates |

Enerable-saving instant manufacturing plant Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Middle scale instant machinery | 1 Set | US$1848 | US$7004 |

| Hot sale automatic Instant Noodle make machinery / production line | 1 Set | US$1151 | US$7290 |

| New desity popular konjac reaLD in knots | 1 Set | US$1999 | US$7414 |

| High quality cheap Instant Noodle manufacture plant | 1 Set | US$1145 | US$5140 |

| dryed instant noodle production line/ noodle make machinery | 1 Set | US$1952 | US$7192 |

| Noodle Steamer machinery/Instant Noodle make machinery | 1 Set | US$1966 | US$6734 |

Copyright © 2017 - 2024Jinan ADO Food Machinery Co.,Ltd. All Rights Reserved