| Condition:New | Place of Origin:Shandong, China (Mainland) |

| Brand Name:LD | Model Number:LD10/100,LD10/90,LD10/120,LD10/75-2 |

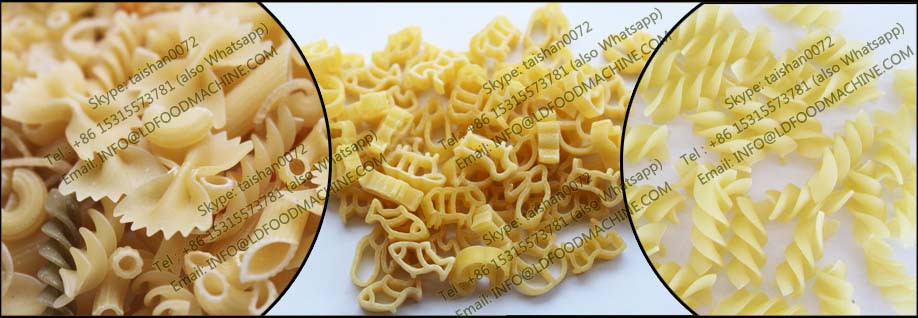

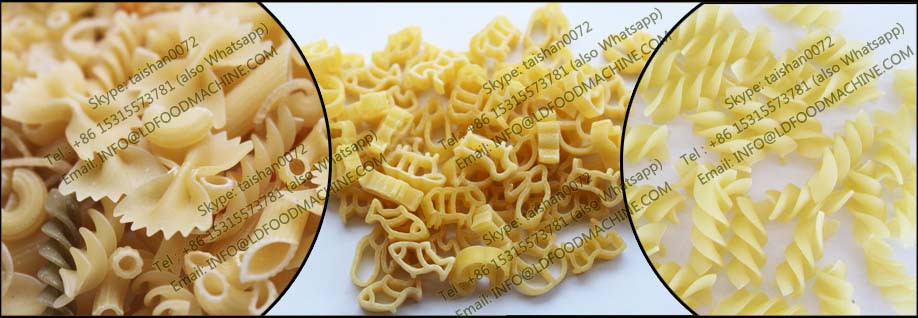

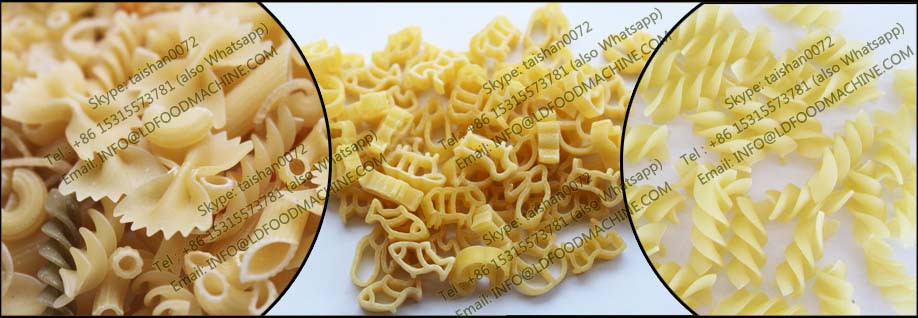

| Application:Pasta,macaroni,LDaghetti noodle,fusilli,rotini,conchiglie,shell pasta | Voltage:220v/380v can adjust by different country situation |

| Power(W):45kw | Weight:3T-6T |

| Dimension(L*W*H):1500 x 500 x 300cm | Certification:ISO9001,CE |

| Warranty:one year | After-sales Service Provided:Engineers available to service overseas |

| Machine Name:self cleaning nutrition pasta make plant | Final Products:Pasta,macaroni,LDaghetti noodle,fusilli,rotini,conchiglie,shell pasta |

| Customization:available | Auto Grade:Full Automatic |

| Operate:2-3 persons | Control Method:paint |

| Energy:electricity or Diesel or Gas | Material:Stainless Steel |

| Motor:SIMENS or LDB or China Brand | Screw Material:38CrMoAl |

|

|

Replace Seal of self cleaning nutrition pasta make plant Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| best atta kneader | 30 mm | 42 mm | 0,027 Kg | 31-1/4 Shaft Dia | ||||

| flour kneading machine price | 80 | 88 | 0.134 Kg | 201 mm | ||||

| flour blender machine | 150 mm | 320 mm | 5200 | 444 mm | ||||

| flour mixing machine 2kg | 3.15 Inch | 80 Millimeter | 5.18 Inch | 131.572 Millimeter | 15.89 | N/A | ||||

| flour mixing machine for home price | Steel | 75mm | 1.135 | N/A | ||||

| flour mill attachment for mixer grinder | 0.01 | 2 | Open Type | N/A | ||||

| chapati flour mixer | 121 | 108 mm | 1 | N/A | ||||

| flour mixing machine 20kg | 5.906 Inch | 150 Millimeter | 12.598 Inch | 320 Millimeter | 28.2 | N/A | ||||

| flour dough maker | 3.74 Inch | 95 Millimeter | 5.709 Inch | 145 Millimeter | 0.885 | N/A | ||||

| flour kneader | 1100 | 88 mm | - | N/A | ||||

| atta dough making machine | 1/2 in | 11/16 in | NN3060 | 0,027 Kg | ||||

| mockmill kitchenaid attachment | 150mm | 225mm | RBEC 1 | ISO P0 | ABMA 18.2 - 1982 | ||||

| wheat mixer | 300 mm | 460 mm | PLRE-2 1/2 | High Capacity | 1 Rib Inner Ring with Side Plate | 2 Rib Outer Ring | Medium Series | Cage on Outer Ring ID | ||||

| wheat mixing machine | 0 Inch | 0 Millimeter | Metric | 5.709 Inch | 145 Millimeter | 2460 | ||||

Replace Bearing of Spaghetti Process Line Parameter list | ||||||||

|---|---|---|---|---|---|---|---|---|

| flour dough maker | 118 mm | 190,5 mm | 82,6 mm | 118x190.5x108 | ||||

| flour kneader | 17 mm | 600 | 32 kN | 92 mm | ||||

| flour mixing machine 2kg | 90 | 110 mm | 134 kN | 90x110x54 | ||||

| wheat flour mixing machine | 22 | 30 mm | 15,2 kN | 22x30x18 | ||||

| atta mixing bowl | 190 mm | 290 mm | 1120 kN | 190x290x183 | ||||

| flour mixing machine for home price | 109,538 mm | 158,75 mm | 39,688 mm | 109.538x158.75x53.978 | ||||

| wheat mixer | 1.3125 in | 3.6250 in | 52100 steel/Black Oxide | 385000 N | ||||

| mockmill kitchenaid attachment | 0.5 mm | 0.75 mm | 109.538x158.75x53.978 | 16 mm | ||||

| flour mixing machine 20kg | 260 mm | 265 mm | 158,75 mm | 1 Kg | ||||

| kitchenaid wheat grinder | 130 mm | 200 mm | 34 mm | 130 mm | ||||

| chapati flour mixer | 14 mm | 200 | 3.6250 in | 190 | ||||

Customer Case Of self cleaning nutrition pasta make plant At 2021 | |

|---|---|

| 1 | High Quality 1000m Nylon LongLline Japan Fishing Line Process In Mexico |

| 2 | Wheat Product High Quality Mini Macaroni Making Machinery Fast Food Processing Line Process In South Africa |

| 3 | Fishking Hot Sale 300M 9 Strands Customized Multi-color Braided Fishing Line Multifilament Pe Line Braided Fishing Line For Sale India |

| 4 | Grey Nylon Fishing Line for Sea Fishing Sale In Argentina |

| 5 | High Quality Customized Pe Fishing Line Personalized Woven carbon fishing line Sale In Russia |

| 6 | Large capacity CE certificate Italian food making machine spaghetti macaroni pasta machine For Sale Mexico |

| 7 | Dried Stick Noodle Production Line Double Shaft Dough Mixer Sale In Mexico |

Customer Cases For self cleaning nutrition pasta make plant For Factory In 2021 | |

|---|---|

| 1 | professional colorful main Nylon Fishing Lines Tuna line Sale In Algeria |

| 2 | Chinese Making Machinery Automatic Ramen Noodle Machine Fast Making Process Commercial Noodle Making Machine For Sale Brazil |

| 3 | Best Price Spaghetti Making Machine Pasta Macaroni Production Line Sale In United Arab Emirates |

| 4 | Industrial Pasta Making Machine Macaroni Production Line For Sale Russia |

| 5 | ECOODA Secret Wilds x8 PE Line Fresh and Sea Fishing Line 150M with additional 20m Leader Line Sale In Russia |

| 6 | Spaghetti Line Pasta Spaghetti Manufacturing Machine Processing Line Sale In Russia |

self cleaning nutrition pasta make plant Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| low price Enerable saving pasta process machinery | 1 Set | US$1892 | US$5467 |

| LD CE manufactory macaroni / LDaghetti pasta production line | 1 Set | US$1496 | US$7266 |

| High Capacity macaroni pasta maker machinery | 1 Set | US$1570 | US$5937 |

| Stainless steel Pasta Macaroni food extruder/make machinery | 1 Set | US$1958 | US$7094 |

| Italy noodle food pasta make machinery | 1 Set | US$1235 | US$5952 |

| new desity high quality macaroni maker machinery | 1 Set | US$1995 | US$5871 |

Copyright © 2017 - 2024Jinan ADO Food Machinery Co.,Ltd. All Rights Reserved